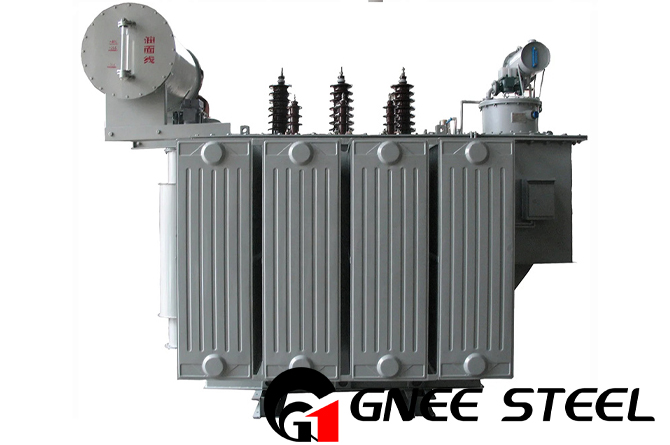

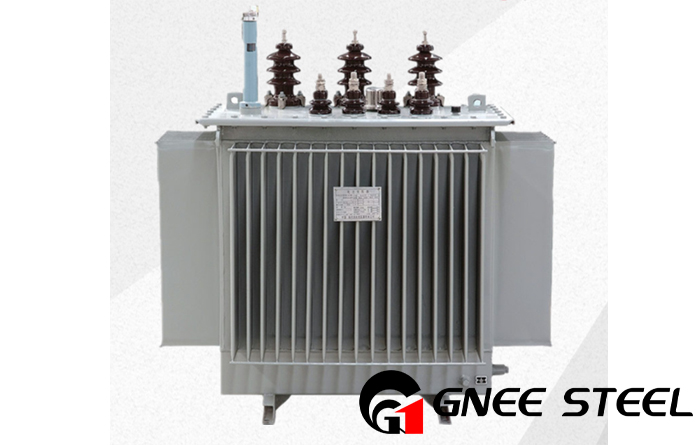

-The core of silicon steel is made of 0.18 ~ 0.3mm orientation silicon steel sheet stacked by punching and shearing, which has good stability.

-The coil is made of pure copper. The acetal enamelled wire is used for high voltage and oxygen-free copper conductor or copper foil for low voltage to improve the short-circuit resistance.

-The Dyn11 connection symbol is used to avoid the influence of higher harmonics. It provides high resistance against uncompensated load and improves the quality of power supply.

-Vacuum oiling is adopted by the transformer to remove bubbles in the core and ensure stable insulating property.

| Rated capacity(kVA) |

Voltage | Maximum no-load losses (W) |

Maximum on-load losses(W) |

Short circuit impedance Uk (% ) |

| 30 | 70 | 505/480 | 4 | |

| 50 | 90 | 730/695 | 4 | |

| 63 | 100 | 870/830 | 4 | |

| 80 | 115 | 1050/1000 | 4 | |

| 100 | 135 | 1265/1200 | 4 | |

| 125 | 150 | 1510/1440 | 4 | |

| 160 | 180 | 1850/1760 | 4 | |

| 200 | 6.0 | 215 | 2185/2080 | 4 |

| 250 | 6.3 | 260 | 2560/2440 | 4 |

| 315 | 10 | 305 | 3065/2920 | 4 |

| 400 | 10.5 | 370 | 3615/3440 | 4 |

| 500 | 11 | 430 | 4330/4120 | 4 |

| 630 | 510 | 4960 | 4.5 | |

| 800 | 630 | 6000 | 4.5 | |

| 1000 | 745 | 8240 | 4.5 | |

| 1250 | 870 | 9600 | 4.5 | |

| 1600 | 1050 | 11600 | 4.5 | |

| 2000 | 1225 | 14640 | 4.5 | |

| 2500 | 1440 | 14840 | 5 |

A: Yes, we are manufacturer. Our factory is in Anyang City, Henan Province.

A: Yes, every product is 1 year quality warrantee under customer correct using the products.

A: In general, it take 2~6weeks and it depend on the different style.

.png)

.png)

.png)

.png)

.jpg)