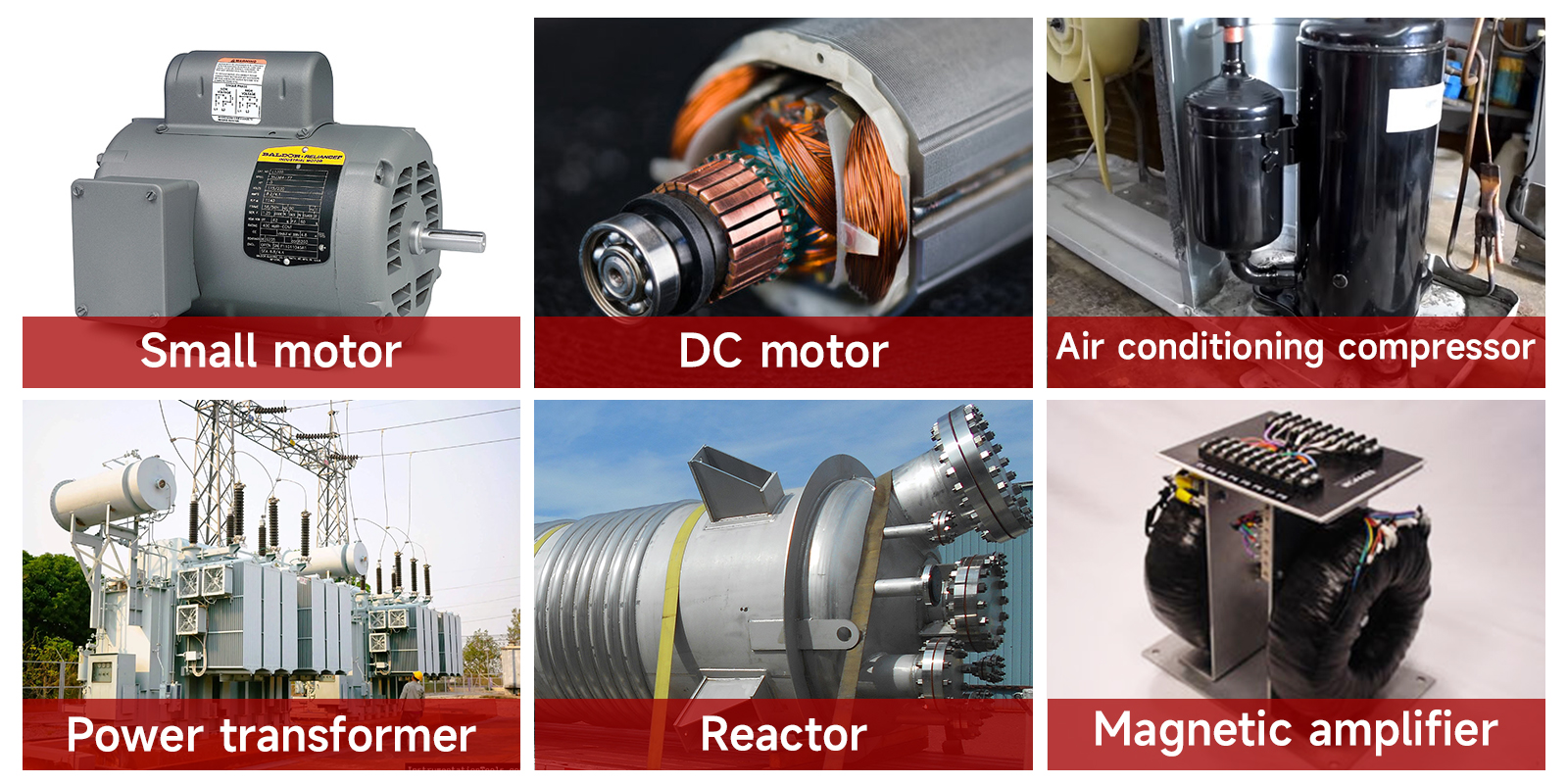

An important component in the production of energy-efficient power equipment is non-oriented silicon steel, a special type of electrical steel. It consists of silicon steel rods, silicon steel sheets, silicon steel coils, and silicon steel strips. The iron core is also a silicon steel sheet. It is usually found in large quantities in power transformers, motors, generators and other electrical equipment.

|

Grade |

Thickness mm |

Density Kg/dm |

Iron Loss(W/Kg) |

Induction |

||||

|

50Hz |

60Hz |

|||||||

|

1.0T |

1.5T |

1.0T |

1.5T |

2500A/m |

5000A/m |

|||

|

35WW230 |

0.35 |

7.6 |

0.78 |

2.05 |

1.05 |

2.65 |

1.56 |

1.65 |

|

35WW25O |

0.89 |

2.22 |

1.13 |

2.8 |

1.57 |

1.66 |

||

|

35WW270 |

0.95 |

2.4 |

1.2 |

2.9 |

1.57 |

1.66 |

||

|

35WW3OO |

7.65 |

1.07 |

2.6 |

1.34 |

3.16 |

1.59 |

1.67 |

|

|

35WW360 |

1.21 |

2.75 |

1.5 |

3.31 |

1.59 |

1.67 |

||

|

35WW400 |

1.21 |

3.I8 |

1.51 |

3.4 |

1.59 |

1.68 |

||

|

35WW440 |

7.7 |

130 |

3.75 |

1.61 |

3.6 |

1.63 |

1.71 |

|

|

5OWW27O |

0.5 |

7.6 |

0.98 |

2.4 |

1.27 |

3.05 |

1.58 |

1.67 |

|

50WW290 |

1.06 |

2.6 |

1.38 |

3.22 |

1.58 |

1.67 |

||

|

50WW310 |

1.18 |

2.75 |

1.52 |

3.49 |

1.58 |

1.67 |

||

|

5OWW35O |

7.65 |

1.2 |

2.95 |

1.53 |

3.53 |

1.6 |

1.68 |

|

|

50WW400 |

1.28 |

3.I5 |

1.61 |

3.66 |

1.6 |

1.68 |

||

|

50WW470 |

7.7 |

1.41 |

3.25 |

2.05 |

4.5 |

1.64 |

1.72 |

|

|

50WW600 |

7.75 |

1.76 |

3-95 |

2.42 |

5.3 |

1.61 |

1.69 |

|

|

5OWW7OO |

1.87 |

4.3 |

2.95 |

6.4 |

1.61 |

1.69 |

||

|

5OWW8OO |

7.8 |

2.18 |

4.85 |

3.64 |

7.68 |

1.63 |

1.71 |

|

|

50WWI000 |

7.85 |

2.49 |

5.6 |

3.92 |

8.22 |

1.66 |

1.74 |

|

|

50WW1300 |

2.52 |

5.9 |

4.27 |

8.92 |

1.67 |

1.75 |

||

.jpg)